DRIVING

POSITIONING

MEASURING

PROJECTS

CONTROLLING

CONTROLLING

Single and Multi-Axes Positioning Controls

MACTROL-ELGO offers simple compact position controls as well as multi-axes controls with customized software for numerous machine applications, e.g. for wood or sheet metal processing.

-

1, 2 or 4 Axes Position Controllers for Metal or Woodworking Machines.

-

LCD display

-

Easy handling

-

Multi-lingual menu navigation

-

Option PID analog output available

-

Reference run

-

Manual-, single- and program mode

-

Modular Axis Control up to 4 axes with control terminal & PLC.

P4011

compact positioning control for

one axis

P40

for 1 or 2 axis / positioning control for wood or sheet metal processing

P40T

programmable touchscreen control / multi-axes positioning control / customized software

P50

P52T

modular positioning control / with control terminal and PLC / for up to 4 axes

CNC control / with touch operation or keypad / for 3 to 4 axes

DRIVING

AGILE Series

-

Agile series provide in a sensor less vector inverter innovations able to boost plant efficiency through open loop vector control of brushless motors, MMC memory cards and web control.

-

Agile smart sensor less frequency inverters are easy to install, program and quick to start-up without the needs of specialized resources.

-

Selectable control functions:

-

V/f control for asynchronous motors

-

Sensor-less vector control for asynchronous motors

-

Sensor-less vector control for brushless motors

-

Power range (AGL402)

0.25 - 11 kW / three-phase 320 V ... 530 V / 50 - 60 Hz (± 10%)

Power range (AGL202)

0.12 - 3 kW / single-phase 200 V ... 240 V / 50 - 60 Hz (± 10%)

0.25 - 7.5 kW / three-phase 200 V ... 240 V / 50 - 60 Hz (± 10%)

Motor compatibility

-

Asynchronous AC motors

-

Permanent magnet synchronous (brushless) motors.

Active/ Active Cube Series

-

A full series of solution & servo drives; compact and flexible, dedicated both to high demanding industrial automation systems and to motion control architectures, in match with servomotors.

-

Selectable Vector control function:

-

Sensor-less control,

-

Sensor-less field oriented control,

-

Field oriented control with speed sensor,

-

Field oriented control of synchronous

-

Servomotors with speed/position sensor

-

Power Range (ACT401)

0.55 - 132 kW / three-phase 360 - 480V/ 50 - 60 Hz (± 10%)

Power Range (ACT201)

0.55 - 9.2 kW / single or three-phase 200 - 240V/ 50 - 60 Hz (± 10%)

Power Range (ACU601)

160 - 400 kW */ three-phase 690 V / 50 Hz - 60 Hz (± 10%)

*1200 kW in parallel connection.

Power Range (ACU401)

0.25 - 400 kW */ three-phase 360 V - 480 V / 50 Hz - 60 Hz (± 10%)

*1200 kW in parallel connection.

Power Range (ACU201)

0.25 - 9.2 kW / single or three-phase 200 V - 240 V / 50 Hz - 60 Hz (± 10%)

AC Servo Motor & Drive Range

MAC-HSM 220 AC Servo Motor Features:

-

Compact architecture and high-power density

-

High Response & Accuracy

-

Super high coercivity rare earth permanent magnet

-

Low Noise & Low Temperature Rise

-

Overheat protection capability (temperature sensor integrated)

-

Strong anti-demagnetization capability

-

Various frame installation size

-

Full-closed design in IP65 Enclosure

MAC-HSD2 AC Servo Drive Features:

-

Wide Speed Range: 0.1 to 5000rpm

-

Strong Overload feature: three times of rated torque.

-

High dynamic feature: Velocity loop bandwidth up to 300Hz, small speed.

-

Various I/O functions: Opto-coupler isolation and programmable functions.

-

Three control mode: position / speed / torque

-

Three kind of pulse and analog command input

-

Various protection functions

-

0.2 to 5.5KW power range

-

2500 PPR encoder, best cost- performance in the market. More encoder type can be customized.

Motion Controllers for Direct Imaging, Printing and Laser Processing

Motion controllers by MACTROL-SIEB & MEYER enable a high-precision movement of the processing heads and synchronization with the machining process at the same time.

SD2S Servo Amplifier

The Smart Drive for Servo Applications:

-

Specialist for high speed applications

-

Single and multi spindle operation

-

Synchronous or asynchronous motor/ spindle

-

Open control, with optional evaluation of speed sensors

-

Closed loop control via evaluation of speed sensors

-

Wide speed range operation up to highest speeds (up to 480,000 rpm/8.000 Hz)

-

Operating via PC, machine interface (analog, I/Os), control unit or CAN-BUS (DeviceNet on request)

-

Saving of up to 64 spindle parameters

-

Load messages

-

Control unit

-

Available in Single Phase 220V & Three Phase 415V.

SD2

The Team Player:

The digital drive system SD2 can be connected to your controller via the real-time bus SERVOLINK 4 using fiber optic cables. This design allows a direct and fast access to all relevant drive parameters.

MC2

The Drive System for Your Machine:

The drive system MC2 is THE solution for machine manufacturers who develop a PC-based application software and look for a well-proven system for the motion tasks.

CNC Controls for Printed Circuit Board Drilling, Routing, Scoring

The CNC controls by MACTROL-SIEB & MEYER and the corresponding drive technology, optimized for mechanical PCB drilling, routing and scoring offer a system solution with the highest precision, productivity and process reliability for your machine.

SD2S Servo Amplifier

Top Technology for your Drilling Machines:

CNC 84.00 is the efficient controller for PCB drilling machines with up to 12 Z-axes, including optional depth control and surface detection.

POSITIONING

Complete measuring and display systems for Absolute & Incremental measurements

In combination with linear and angle encoders MACTROL-ELGO position indicators form a closed system for the direct visualization of the measured values for up to three axes. The self-sufficient, battery-powered measurement and display systems have a very compact design and can easily be mounted without any wiring or cables. Therefore they are especially suitable for the use in small machines and for modernizations. There are also indicators available, which can communicate to a superior system by interface.

P4011

compact positioning control for

one axis

P40

for 1 or 2 axis / positioning control for wood or sheet metal processing

P40T

programmable touchscreen control / multi-axes positioning control / customized software

MEASURING

Non-contact measuring technology

Non-contact and wear-free linear, angle and rotary measurement technology by MACTROL-ELGO offers solutions for all applications and positioning tasks in which lengths, angles, speeds and inclinations are to be detected and measured. Complete the measuring solutions with the right accessories.

.

LIMAX shaft information systems use magnetic tape technology to record the position of the elevator car in the shaft with high precision.

Magnetic Absolute Linear Encoders

The absolute linear magnetic measuring systems with resolution up to 1 µm are particularly suitable for dynamic applications, where precision and safety are required.

RESOLUTION UP TO 0.001 MM

EXAM-HI

high resolution 1 µm / for dynamic processes / ideally suited for use in linear drives

GSA2

guided linear encoder unit / high resolution 1 µm

FMAX

guided absolute measuring system / for measuring lengths up to 650 mm / in unguided version also suitable for angle measurements

FMAX2 I FMAX3

absolute measuring system for linear and rotary applications / ideal for motor feedback Systems / two versions with different max. measuring lengths

RESOLUTION UP TO 0.01 MM

EMAX I EMAL

10 µm Resolution / compact and bus-compatible absolute measuring System / for measuring lengths up to 20 m / two designs / IO-Link interface possible

EMAX ENCODER WITH IO LINK

EMAX | EMAL with integrated interface IO link

EMAX 2

10 µm resolution / extremely compact design for confined installation situations / for measuring lengths up to 20 m

RESOLUTION UP TO 1 MM

MAX3

1 mm resolution / extremely compact sensor design / high protection class up to IP69K

BMIX

1 mm Resolution / battery-supported quasi absolute measurement System / optionally with analogue output (voltage or current) or CANopen

LIMAX2

1 mm standard Resolution / for measuring distances up to 260 m / speeds up to 10 m/s / with integrated tape guide or unguided

MAX1

1 mm Standard resolution / for measuring distances up to 524 m / housing length of only 98 mm / SSI interface

IMAX

1 mm resolution / compact, auto-referencing, quasi-absolute System / for measuring lengths up to 1048 m (CANopen) or 262 m (SSI)

Magnetic Incremental Linear Encoders

The incremental linear encoders allow contacless and wear-free measurements and represent a cost-effective alternative for many machine requirements and applications.

HIGH RESOLUTION MEASURING SYSTEMS UP TO 0.001 ΜM

HMIX2

high-resolution sensor technology / for very precise positioning / high repeat accuracy / compact housing

EMIX23

high resolution 1 µm / small design / integrated evaluation electronics

HMIX1X

1 µm resolution / ideal for precision motor feedback

GSI2

guided system / resolution up to 1 µm / for use in press brakes

EMIX1X

compared to HMIX1X larger reading distance possible / ideal for motor feedback

GSI4

high-quality linear unit / roller guide / resolution 1 µm / high accuracy

PMIX

digital potentiometer / with sensors of the LMIX- or EMIX-series / can be combined with battery operated IZ measuring and display systems

MEASURING SYSTEMS UP TO 0.01 MM RESOLUTION

EMIX1

0.01 mm resolution / small sensor head / external evaluation electronics / encoder compatible square wave signal outputs in HTL or TTL format

EMIX2

0.01 mm resolution / small sensor head with integrated evaluation electronics / 90° sensor mounting possible / for linear and radial measurements

LMIX22

resolution adjustable to 2.5 µm / with index and optional reference pulse

GMIX1A

adjustable resolution up to max. 0.01 mm / speed monitoring - Vmax output e.g. for woodworking machines

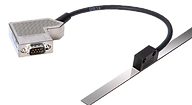

FOW I FLW

linear measuring unit with precision carriage open or closed / with EMIX or LMIX sensor technology or battery powered IZ measuring and display units

MEASURING SYSTEMS UP TO 0.01 MM RESOLUTION

LMIX1

25 µm resolution / extremely compact design / sensors and evaluation electronics are located in separate housings

LMIX2

25 µm resolution / sensors and evaluation electronics are integrated in one housing

KMIX2

25 µm resolution / easy mounting via hole possible

RMIX2

25 µm resolution / for highly dynamic applications / ideal also for rotary applications with high rotational speed

MEASURING SYSTEMS UP TO 1 MM RESOLUTION

DMIX1

1 mm resolution / external evaluation electronics (in connector) / read distance up to 10 mm

DMIX3

1 mm resolution / integrated evaluation electronics / reading distance up to 10 mm / freely selectable reference pulse

BMIX

quasi-absolute, battery-supported length measuring system / position detection even in de-energized state

GMIX2

2.5 mm resolution / small sensor head with integrated evaluation electronics / predestined for applications in warehouse and conveyor technology

INCREMENTAL MEASURING SYSTEMS WITH SIN/COS SIGNAL OUTPUTS

HMSC1

1 mm signal period / external evaluation electronics

EMSC1

2 mm signal period / small sensor with external evaluation electronics

LMSC1

5 mm signal period / small sensor with external evaluation electronics

LMSC2

5 mm signal period / small design despite integrated evaluation electronics / vertical mounting position to magnetic tape possible

EMSC2